3D printing plays a crucial role in sustainable manufacturing by reducing waste, energy consumption, and transportation emissions. With its ability to create complex designs and produce customized products on-demand, 3D printing minimizes material wastage and eliminates the need for excessive inventory. Additionally, it offers the opportunity to use recycled materials and biodegradable alternatives, further contributing to sustainable practices. By integrating 3D printing into manufacturing processes, companies can significantly reduce their environmental impact and move towards a more sustainable future.

The Role of 3D Printing in Sustainable Manufacturing has revolutionized the way products are created, offering numerous benefits for both the environment and businesses. With 3D printing, items can be made on-demand, reducing waste and eliminating the need for large-scale manufacturing facilities. This innovative technology allows for the creation of complex designs with intricate details, making it a game-changer in various industries.

One of the significant aspects of 3D printing in sustainable manufacturing is its ability to reduce material waste. Traditional manufacturing methods often result in a significant amount of material being discarded as a byproduct. However, with 3D printing, materials can be used more efficiently, resulting in minimal wasted resources. This not only reduces costs for businesses but also contributes to a more sustainable production process. According to a study, 3D printing can save up to 63% of the energy compared to conventional manufacturing methods, highlighting its potential to drive environmentally-friendly practices.

The Advantages of 3D Printing in Sustainable Manufacturing

Sustainable manufacturing is a growing focus in the industrial sector as companies strive to reduce their environmental impact and promote sustainable practices. One technology that has emerged as a game-changer in the field is 3D printing. Also known as additive manufacturing, 3D printing offers numerous advantages in terms of sustainability. By utilizing this technology, manufacturers can reduce waste, energy consumption, and carbon emissions throughout the manufacturing process. Furthermore, 3D printing enables the development of lightweight and durable products, optimizing material usage and reducing transportation costs. Overall, the role of 3D printing in sustainable manufacturing is instrumental in creating a more environmentally friendly and efficient industry.

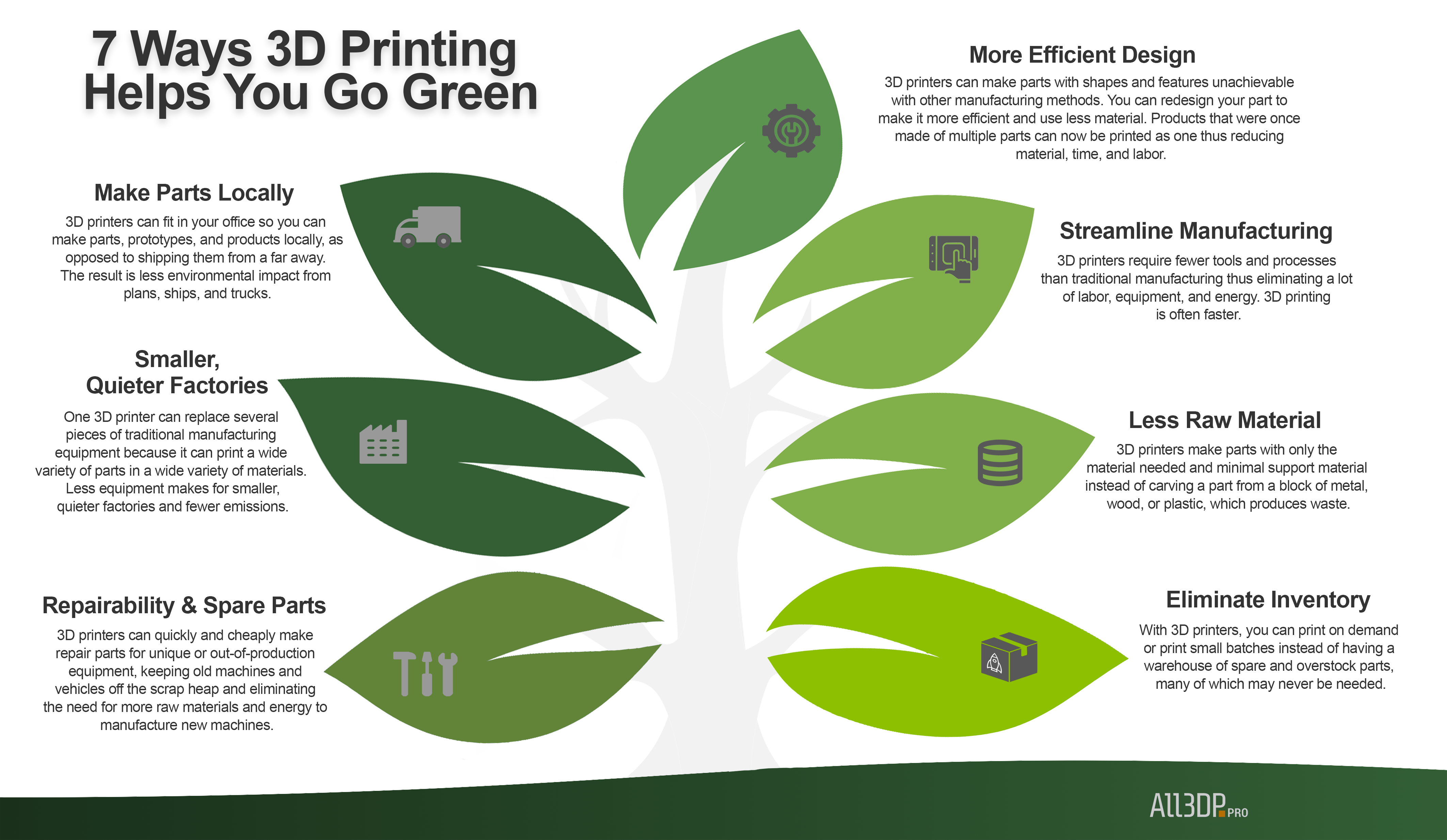

One of the primary advantages of 3D printing in sustainable manufacturing is the reduction of waste. Traditional manufacturing methods often result in a significant amount of material waste, as parts and components are cut or shaped from larger materials. In contrast, 3D printing builds products layer by layer, using only the necessary amount of material, resulting in minimal waste. This reduction in waste not only contributes to a more sustainable manufacturing process but also helps companies save costs by minimizing material usage.

Furthermore, 3D printing offers opportunities for the use of sustainable materials. With traditional manufacturing processes, companies are often limited to a specific range of materials that may have a higher environmental impact. However, in 3D printing, there is a wider range of material options available, including eco-friendly and bio-based materials. These sustainable materials can be used to create products with reduced carbon footprints and lower environmental impact.

The Role of 3D Printing in Sustainable Manufacturing – Key Takeaways

- 3D printing enables the production of complex and customized designs, reducing overall waste in manufacturing processes.

- Using sustainable materials for 3D printing, such as biodegradable or recycled plastics, contributes to environmental conservation.

- 3D printing can minimize transportation emissions by localizing production and reducing the need for long-distance shipping.

- The ability to create spare parts on-demand through 3D printing reduces the need for excess inventory and promotes a circular economy.

- Adopting 3D printing in manufacturing can lead to energy savings by reducing the energy-intensive steps of traditional manufacturing.

3D printing plays a vital role in sustainable manufacturing by reducing waste and conserving resources. Through additive manufacturing, products can be produced with minimal material usage and without the need for wasteful assembly processes.

This technology also enables the creation of complex designs that optimize material use and improve product performance. By utilizing 3D printing, manufacturers can reduce their carbon footprint and energy consumption, making it a more environmentally friendly and sustainable manufacturing process.

Additionally, 3D printing allows for on-demand production, eliminating the need for excessive inventory and reducing transportation emissions. This not only reduces costs but also promotes a more efficient and sustainable supply chain.

In conclusion, 3D printing offers significant advantages in sustainable manufacturing by reducing waste, conserving resources, and optimizing production processes. It paves the way for a more eco-friendly and efficient approach to manufacturing.